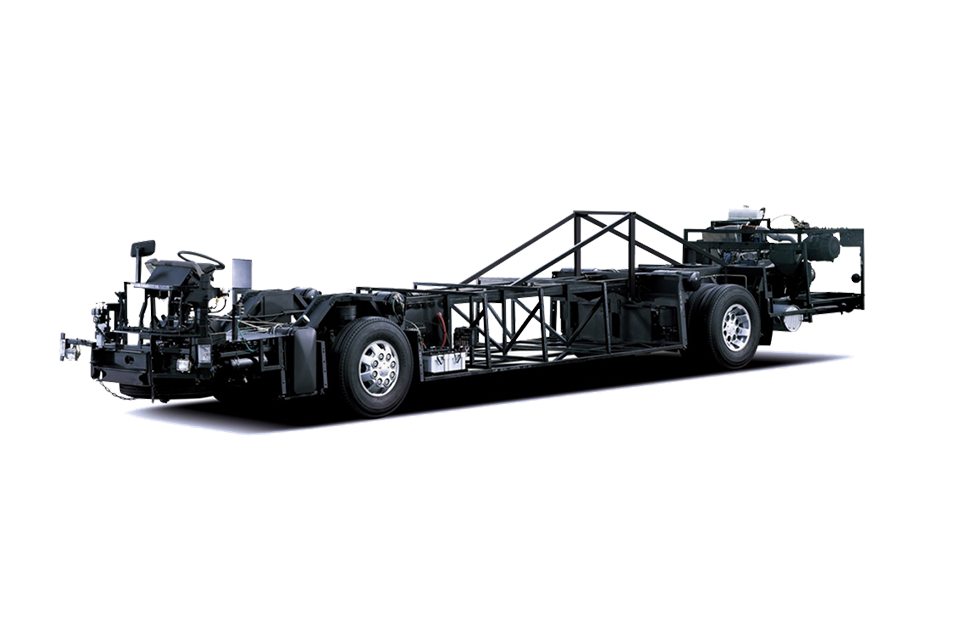

KM500 Series

Decontamination Vehicle

This vehicle is for precise decontamination of the human body; system and area with deck space and structural strength for mounting fixed water tank, crane, pump, boiler for water tank heating, decontamination system, poison neutralizing agent, and auxiliary systems. Modified 5-ton vehicle with improved capability compared with 2-1/2 ton decontamination vehicle.

This vehicle is for precise decontamination of the human body; system and area with deck space and structural strength for mounting fixed water tank, crane, pump, boiler for water tank heating, decontamination system, poison neutralizing agent, and auxiliary systems. Modified 5-ton vehicle with improved capability compared with 2-1/2 ton decontamination vehicle.

FEATURES

-

Deck

Deck space and structural strength for mounting a fixed water tank, crane, pump, a boiler for a water tank heating, a decontamination system, a poison neutralizing agent, and auxiliary systems.

-

Fixed water tank on vehicle

Fixed water tank on vehicle of double-wall insulation structure that is capable of storing 2,500 liters and of heating water by making use of the boiler for heating the water tank.

-

Fixed water tank on vehicle

The crane is operated by a motor and hydraulic force. It has booms that can expand up to three levels. It is mounted on top of the deck for the easy loading and unloading of cargo.

-

Pump

Equipment necessary for supplying water to fixed water tank on vehicle or patched water tank; runs on gasoline ; detachable.

-

Boiler for heating the water tank

Consists of a burner, heat exchanger, controller, frame, and electric system for heating water in the fixed water tank that is on the vehicle.

-

Pre-and post-treatment system

Consists of an air-cooling diesel engine, pump, control box, boiler, generator, battery and frame. It is detachable.

-

Main processing system for equipment

Consists of an air-cooling diesel engine, pump, control box, generator, battery, powder injector, mixer, and frame. It has a hopper capacity for storing powdered poison neutralizing agents for operations in sequence from 1 to 5

-

Main processing system for area

Consists of an air-cooling diesel engine, pump, control box, generator, battery, powder injector, mixer, and frame. It has a hopper capacity for storing powdered poison neutralizing agents for one operation.

-

Sprayer of area poison neutralizing agent

Mounted on the bottom rear of the vehicle.

-

Auxiliaray equipment

Field shower system of prefabricated structure with partitions; patch-type water tank installed with air injection mode; decontamination bag of patch type structure, fixed shower system of prefabricated structure mounted on the rear side of deck.

KM500 Series Decontamination Vehicle

| Type | Technical Data | |

|---|---|---|

| Overall length | mm | 10,000 |

| Overall width | mm | 3,000 |

| Overall height | mm | 3,300 |

| GVW | kg | 19,000 |

| Max. Speed | km/h | 88 |

| Max. Horsepower | ps@rpm | 270@2,200 |

| Max. Torque | kg·m@rpm | 98@1,400 |

| Gradeability | % | 60 |

| Fording Depth | mm | 760 |

| Ground Clearance | mm | 270 |

| Min. Turning Radius | m | 14.5 |

| Range | km | 600 |

Mounted equipment

| Item | Special equipment | |

|---|---|---|

| Power | Power embedded in each equipment | |

| Operators | 5 persons | |

| Water tank | Type | Double tank insulation structure |

| Capacity (ℓ) | 2,500 | |

| Water supplier | Type | Self-absorptive centrifugal pump (independent operation) |

| Vertical descending once-through boiler | 2,500 | |

| Crane | Type | Motor-driven; expandable up to three level |

| Maximum craning capability | 600 kg when the boom length is 4.1m | |

| Item | Decontamination capability | |

|---|---|---|

| Agitating mode of neutralizing agent | Continuous agitation | |

| Features of neutralization | Decontamination of human body | Operates the human body decontamination chamber |

| System neutralization | Operates the precision decontamination chamber | |

| Area neutralization | Automatic spraying | |

| Neutralizing agent | Decontamination of human body | Water + liquid detergent |

| System neutralization | Emulsion | |

| Area neutralization | Soluble agent | |

| Capability of decontamination | Decontamination of human body | 144 persons/hour |

| System neutralization | 2½ ton cargo 18 trucks/once | |

| Area neutralization | 1,632 ㎡ | |

| Generation of agent | System neutralization | 24 ℓ/min., continuous agitation |

| Area neutralization | 280 ℓ/min., continuous agitation | |

| Hot water supply | 5,000 ℓ/h (50℃) 1,600 ℓ/h (90℃) |

|

| Steam supply | Wet steam | 800 ℓ/h (140℃) |

| Dry steam | 800 ℓ/h (190℃) | |

Home

Home